IS, ISB, ISR type centrifugal pump system

Product Overview:

IS series single stage single suction (axial suction) centrifugal pump, suitable for industrial and urban water supply, drainage, can also be used for agricultural irrigation and drainage. For conveying clean water or other liquids with physical and chemical properties similar to clean water at a temperature not higher than 80℃.

ISB series centrifugal pump IS improved on the basis of IS pump design, this series of products have the advantages of high efficiency and energy saving, low noise, no leakage, reliable performance, its economic and technical performance has reached the high quality level of similar foreign products, it is a kind of replacement products, he has the following characteristics:

1. Wide use: applicable to a variety of refrigeration systems, especially to meet the air-conditioning of high-rise buildings, who system with pump pressure requirements, also applicable to factories, mines, cities, power stations, water conservancy and other engineering drainage or water supply pump.

2. Good versatility: In order to achieve the versatility of this type of pump parts, the installation size of the ISB pump's pump head and bottom plate IS exactly the same as that of the IS pump, which is conducive to the replacement of the old pump.

3. Convenient disassembly and assembly: the pump body and pump cover part of ISB pump are separated from the back of the impeller, that is, the rear door type structure. The advantage is convenient maintenance.

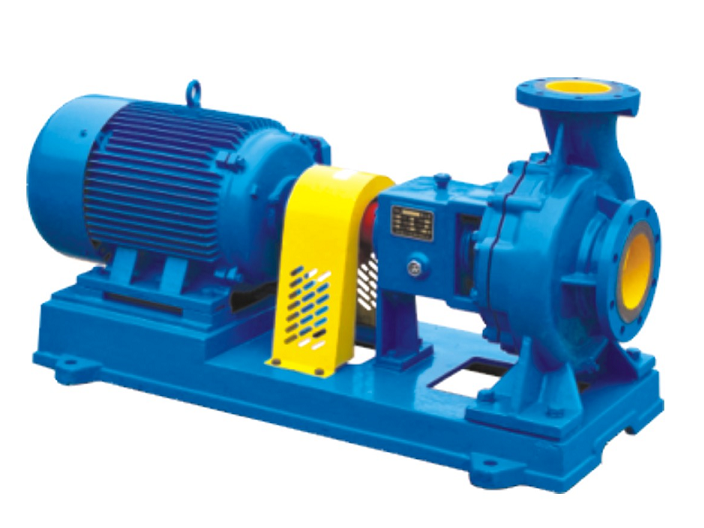

Type A pump system is designed according to the performance and size specified in the international standard S02858. It is mainly composed of pump body, pump cover, impeller, shaft, seal ring, shaft sleeve and suspension bearing components. ISB type pump is mainly composed of pump body, pump cover, impeller, shaft, sealing ring, mechanical seal, bearing body and so on. ISR pump IS basically the same as IS pump, only in the pump cover shaft seal is equipped with water cooling chamber, used to reliably cool packing, shaft and prevent heat transfer to the bearing. Adopt high temperature resistant polyfour gas packing.

The pump housing (i.e. the pump body pump cover) constitutes the pump studio. Impeller, shaft and rolling bearing are the rotor of the pump. The suspension bearing component supports the rotor component of the pump, and the rolling bearing bears the radial and axial force of the pump.

In order to balance the axial force of the pump, most pump impeller front and rear are sealed ring, and a balance hole is provided on the impeller rear cover plate

In order to avoid shaft wear, shaft sleeve protection is installed in the part of the shaft through the packing chamber, and 0 type sealing ring is installed between the shaft sleeve and the shaft to prevent air intake or water leakage along the matching surface.

IS, ISB, ISR pump transmission mode is connected with the motor through the elastic coupling. The direction of rotation of the pump, from the driving end, are clockwise rotation.

If the taper pipe is used, that is, the suction pipe diameter is the same as the discharge pipe diameter, the discharge flange connection size is the same as the suction flange.

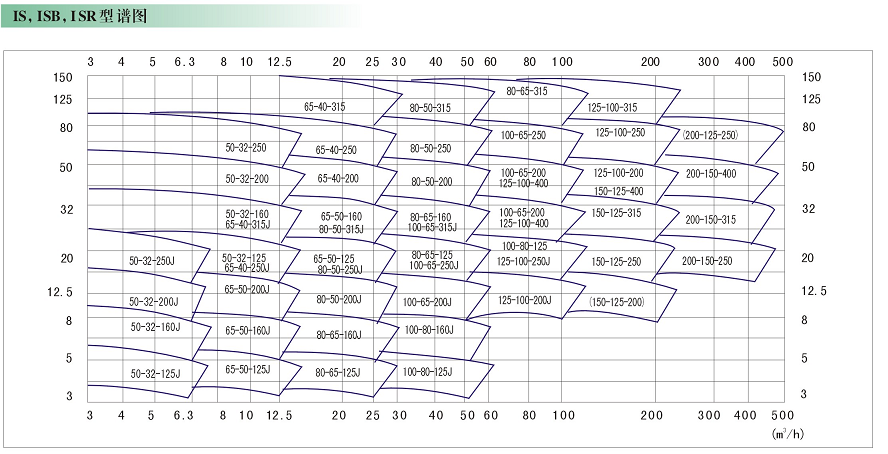

Performance range

According to rated operating points

Rotation speed :2900r/min, 1450r/min

Heart :50~200mm

Inlet diameter

Flow rate :6.3~400m³/h

Head :5~128

When the user has special requirements for pump performance, material, according to the user's requirements to give special.

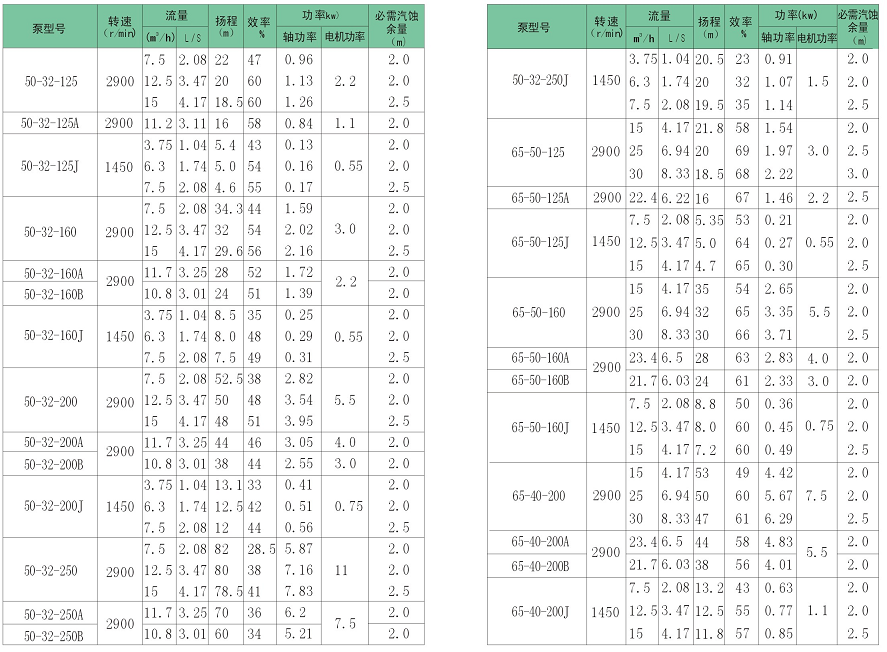

Performance parameters: